Norweld: A proud Australian Made success story

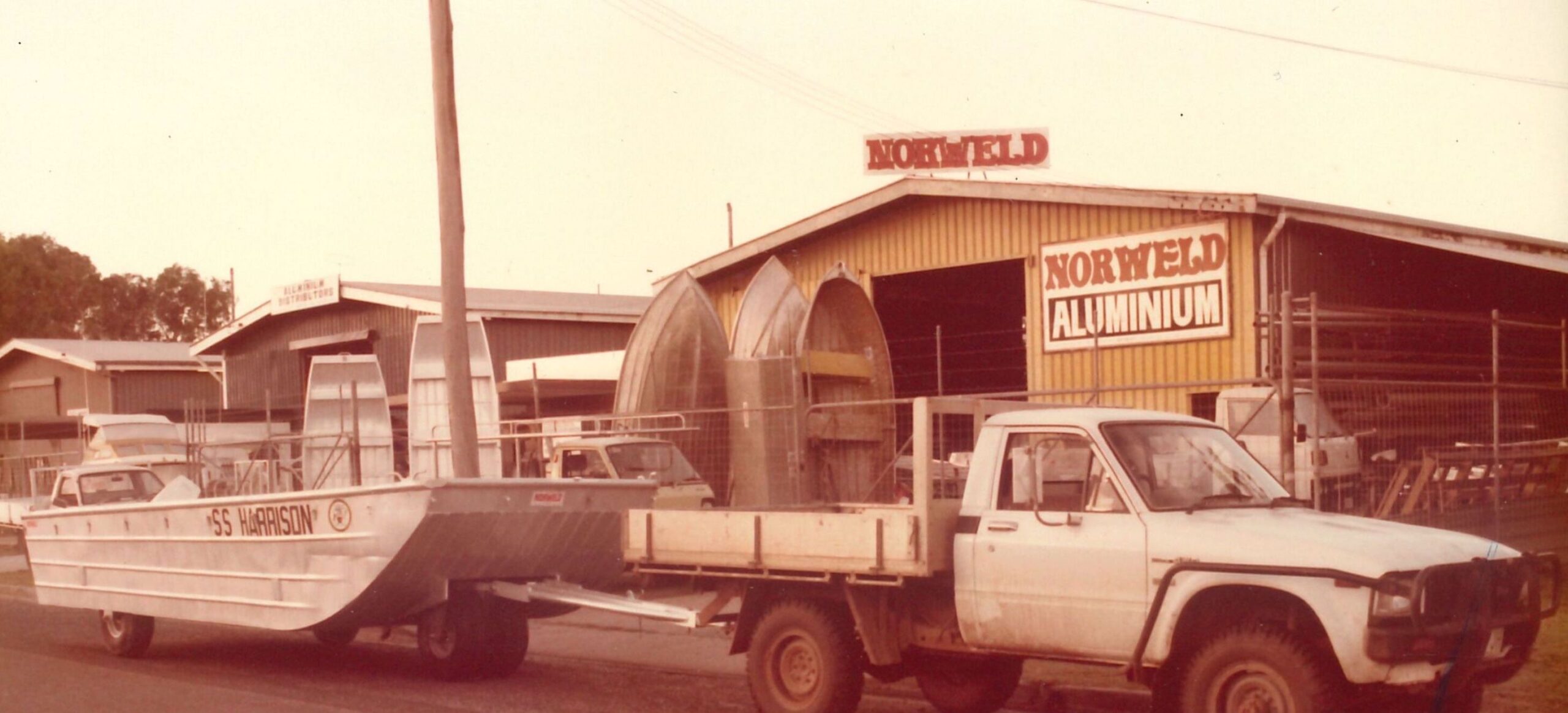

During the 1970-1980’s, Norweld was the backbone of the tourism industry, building barges, glass bottom boats, gangways, ladders, tanks and the very pontoons still used today by industry giants like Quicksilver at Moore Reef and Big Cat at Green Island. However, big changes swept through following the 1989 Australian pilots’ strike which crippled the local tourism industry, leading Norweld to pivot into diverse markets, including punts, motor vehicle accessories, material sales, aluminium repairs and fabrications.

The onset of the GFC tested Norweld’s resilience further, prompting a reevaluation of its strategies amidst Cairns’ boom-or-bust economy. One thing the team identified during these uncertain times, was the increasing popularity of dual cab 4x4s in Northern Australia. Though Norweld had built the odd ute tray and canopy, it wasn’t until the team took a step back to reexamine their processes that they uncovered an untapped opportunity.

Recognising a gap in the market for heavy-duty, fully welded trays, they embarked on a journey of innovation and development. Despite facing numerous obstacles and a lot of hard work, they bounded on, establishing a dedicated division within Norweld to focus on sales and marketing of their ute trays and canopies.

With an increase in demand, a growing team and expanding operations, they outgrew their humble shed and looked for additional space to accommodate their growing ventures. Like all small businesses, challenges persisted, yet not once did that deter them from pursuing their vision.

By early 2015, with a workforce of 25 and growing, they set their sights on a new space, laying the groundwork for a new era of growth.

Fast forward to 2025, Norweld Australia stands tall with a formidable team of 171, each team member contributing to the legacy of Norweld with every ute tray and canopy they build.

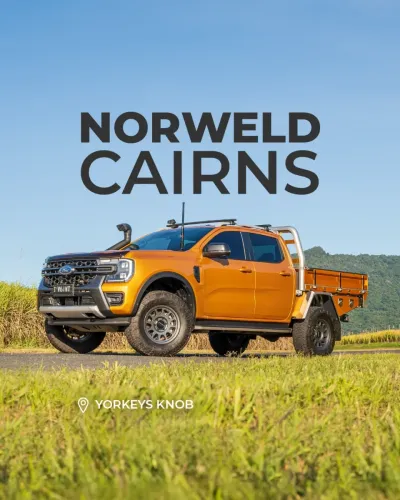

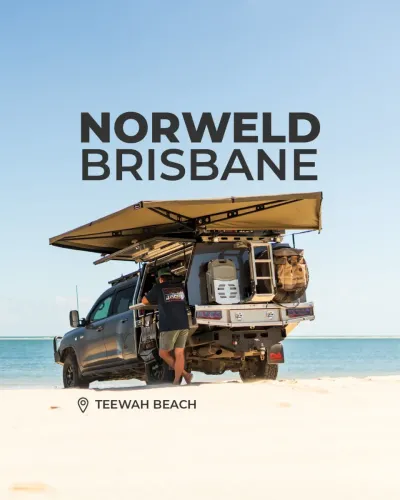

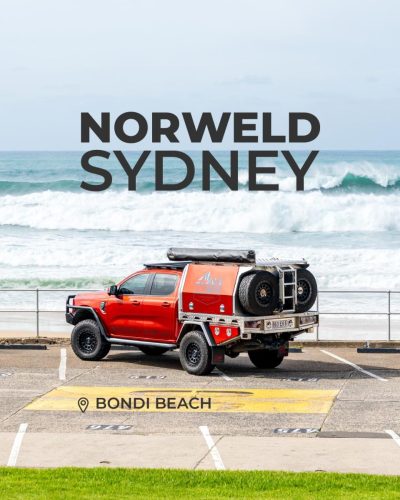

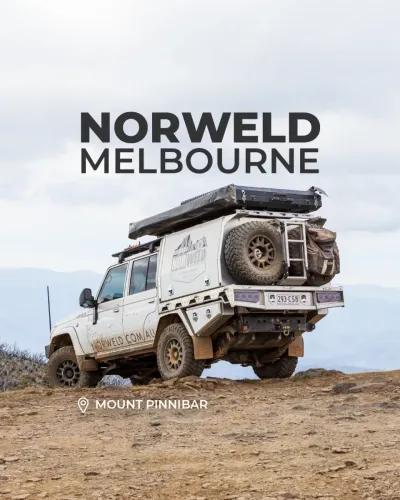

Today, Norweld’s manufacturing footprint spans Cairns, Brisbane and Townsville. Cairns remains our HQ and operates on a batch production system with TIG welding, CNC routing, in-house paint booths and our LBD laser cutter, giving us unmatched precision and control in every build which means we can get a superior product out to our customers quickly. Brisbane runs a one-piece flow production line, producing a tray approximately every 52 minutes, while Townsville services North Queensland with its own factory setup for welding, CNC routing and assembly.

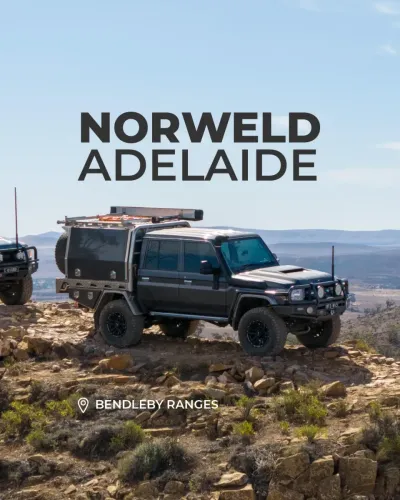

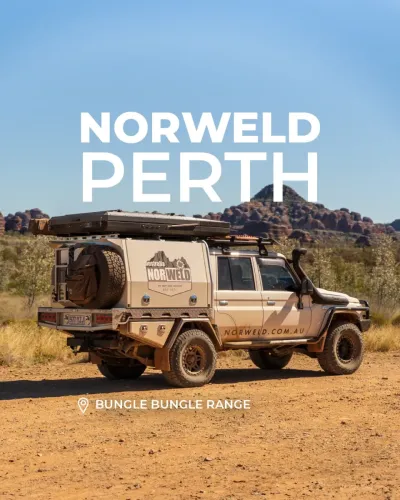

Supporting these manufacturing hubs are five additional branches in Newcastle, Sydney, Melbourne, Adelaide and Perth, providing local sales, fitment and after-sales support to Norweld customers nationwide.

At the helm of Norweld stand three visionary leaders, impassioned by excellence and committed to upholding the spirit of Australian manufacturing.

Norweld Directors: Committed to Australian Made

Jaime McIntosh | Managing Director Norweld [Right]

“We are very passionate about keeping manufacturing in Australia. Since 1971, Norweld has been offering a lifetime guarantee for all its craftsmanship. 53 years and still going strong, ensuring Australia does not lose its manufacturing capability. It would be more cost beneficial for us to offshore our operation but that goes against the Norweld DNA. We firmly believe in supporting the next generation, providing them with the opportunity to learn valuable trades and contribute meaningfully to society. Through our apprenticeship programs, Norweld ensures that our skills are passed down to the next generation.”

Steve Umback | Operations Director Norweld [Left]

“For decades Australian manufacturers have decided to reduce costs by offshoring their labour-intensive manufacturing processes. This goes against the DNA of all Norweld staff as we pride ourselves on not taking the easy road and pushing back against the trends of other companies to explore the bounds of innovations. Through investing heavily in design, advanced manufacturing techniques, process optimisation, and most importantly our people we have shown that Australia has the right ingredients to be a competitive manufacturer on the world field. By working smarter and not harder we have shown the true Australian “have a go” mindset can overcome complex challenges to deliver world class engineering and manufacturing technologies.”

Isaac Edmiston | Special Projects Director Norweld [Centre]

“A key source of pride for me and many of the Norweld team is our commitment to building the best trays and canopies on the market. From humble beginnings as a small Cairns-based fabrication business to a nationally recognised brand in the Australian 4×4 industry with branches nationwide. With our expansion into international markets, we have managed to export Norweld trays and canopies to 6 continents. “Australian Made” is synonymous with toughness, and Norweld Australia has proven that our trays and canopies can handle the harshest environments imaginable. From the Simpson Desert and Kimberleys in Australia to the Rub’al-Khali in Saudi Arabia, the Skeleton Coast in Namibia to the California Crest Trail in the United States, Norweld Trays and Canopies cover millions of kilometers every year in the hands of our customers. This alone is a testament to our commitment to quality, service, and Australian manufacturing.”

As Norweld moves forward, they remain focused on their mission to craft dreams and build legacies for generations to come. Here’s to the next chapter of Norweld – where #AustralianMadeWeek isn’t just a tagline; it’s a way of life, proudly embraced and fiercely preserved.

Check out Australian Made: The Norweld Way to discover why choosing Australian Made isn’t just about quality – it’s also about supporting our economy, local jobs, communities and future generations.